Our price of these cylinder heads is higher than the price of other suppliers, for the following good reasons:

- 1. The valve guides are checked and reamed if needed. Some guides require upto 0.02 mm reaming. Without these adjustments, the valves would get stuck quickly.

- 2. We replace the supplied non-rotating valves with rotating valves.

- 3. The cylinder head mating surfaces are flattened in case of visible/palpable edges in the mating plane or “curved” surfaces. The depth of the mating surface is measured, to make sure that the height of the collar on the cylinder does not exceed the depth of the cylinder head. The amount of material that needs to be removed is usually between 0.10 and 0.14 mm

- 4. Valves are vacuum tested for leaks. In some cases the valve seats need to be regrinded because they don’t align with the valve guides / valves.

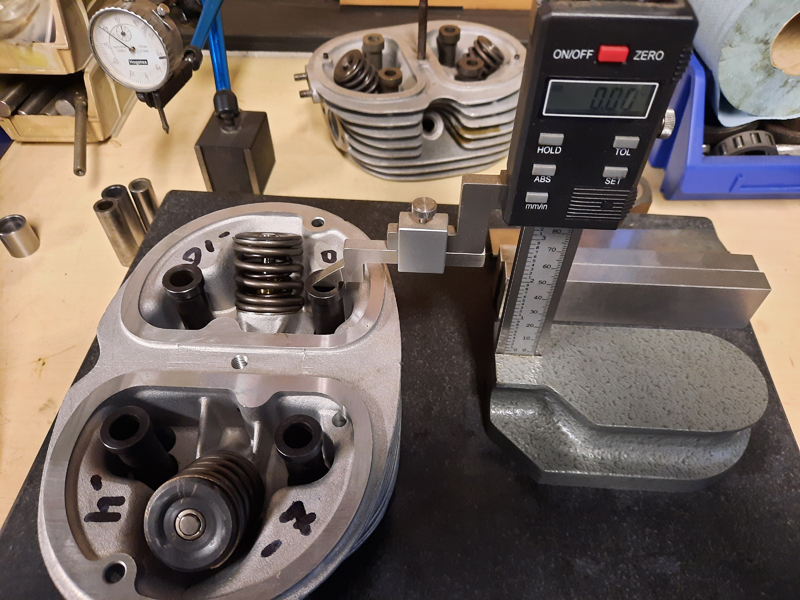

- 5. The height of the 4 cylinder head sleeves is measured and shims are added if necessary to ensure that the height difference between adjacent sleeves does not exceed 0.05mm. The highest sleeve is marked “0” and any deviation from the “0” sleeve is marked next to each sleeve. (e.g. “-16” means 0.16 mm lower)

Note: only a height difference between the cylinder head sleeves supporting the same rocker arm needs to be reduced.

In this case, no need to use a shim on the “-4” and “-7” sleeves, because the difference is only 0.03 mm. The height difference between the “-16” and “0” sleeved is reduced to 0.04 mm by adding a 0.20 mm shim to the “-16” sleeve.

An edge is clearly visible in the mating surface on this cylinder head. This would inevitably lead to a leaking cylinder head gasket:

Cylinder head after resurfacing: