With hardly any new carburetors being produced by BING for the < 1969 BMW mono and twin motorcycles, it’s getting increasingly important to be able to repair and recondition the used original carburetors.

Luckily, special parts and tools are available nowadays to restore the carburetors to a good working condition.

A. Idle mix screw: very often, the M7 x 0.75 mm screw thread in the carburetor housing is worn out. There are 2 good solutions to this problem.

1. drill the threaded hole to 7.2 mm – cut M8 x 0.75 mm screw thread – install the idle mix screw with PN 13110039181.7. Part of this screw has M8 x 0.75 mm and part of it has M7 x 0.75 mm so that the original sleeve, cap and lock screw can be used.

2. drill the threaded hole to 7.2 mm – place a threaded bushing with M8 x 0.75 mm (outside) and M7 x 0.75 mm (inside) – you can now re-use the original idle mix screw.

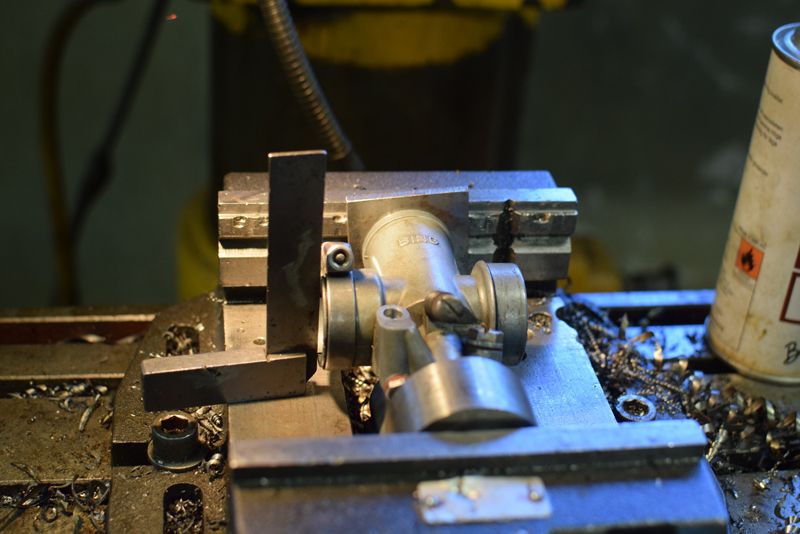

Obviously it is very critical to drill the hole exactly aligned with the threaded hole, else the tip of the idle mix screw will not fit in the small hole at the bottom of the threaded hole. If no proper tools are available, this is best left to a specialist. The threaded bushing is made from alu-bronze, a material with excellent wear resistance properties (PN13110039181.6)

At the bottom of this page a few photos from a customer who did this this work himself.

B. Slide stop screw: same problem here, the M6 x 0.75 mm screw thread can be worn out. No oversized stop screws are currently available, at least not in the original model. Solution here is to drill the hole to 6.2 mm, cut M7 x 0.75 mm screw thread and place an alu-bronze M7/M6 x 0.75 threaded bushing. This allows for the use of the original stop screw.

C. Carburetor slide: a worn out carburetor housing and worn slide causes difficulties with tuning the carburetor. Oversized slides are available: PN 13110039119.1 (+0.2 mm = Ø 27.2 mm) and PN 13110039116.A (+0,5 mm = Ø 30.0 mm). Boring the carburetor housing to the required size is best left to a specialist.

D. Float cover screw: worn screw thread in the housing. If there is still a little bit of screw thread height left, an oversized screw can be used: PN 13110039156.7 hex screw with M5.3 screw thread. If the screw thread is completely gone, a double sided threaded bushing can be installed to bring the screw thread back to the original M5 thread.

E. Screw caps: for the various screw caps found on the BING carburetors, caps with over-sized screw threads are available, such as PN13110039197.7 screw cap main jet M15.5 x 1 or PN 13110039196.7 screw plug M8 x 0.75 Bing 140-706

F. Needle jet screw thread: worn screw thread in the carburetor housing can be repaired with a M8 / M6 x 0.75 (alu-bronze) threaded bushing

G. Float cover: when the float cover is bent as a result of over-tightening, the float cover can be “flattened” in a lathe. However, this will weaken the float cover, and therefor requires extra careful tightening of the float cover screws

H. Flange: also the carburetor flanges are ususally bent, causing air leaks and therefor problems with tuning. This can be easily repaired using a of sheet of glass and waterproof sandpaper

I. Slide cover plate: if the tab that holds the cover in position is broken off, it can be repaired with a 2 component Alu epoxy resin.

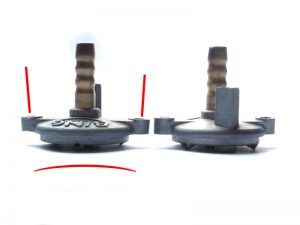

Photos from a customer who installed the alu-bronze bushing for the idle mix screw himself:

He is satisfied with the result, but using a drill and tap for blind holes would have given a deeper threaded hole: this way a longer part of the bushing could have been used