A frequently asked question is how to fix a leakage of the idle mixing screw.

Further tightening the nut of the idle mix screw is certainly not the solution: holes have been drilled in the idle mix screw which connects the idle mix chamber to the the outside air. If fuel leaks out through the same bore, it simply means that the fuel level in the float bowl is too high. (assuming that the bike is on the center stand, if the motorcycle is placed on the side stand, there is a greater risk of leakage)

If the carbs keep leaking, it’s mostly because the float / and or float needle are not doing their job.

– The float could be leaking, which makes it heavier. You can detect this by shaking the float. If you hear fuel “sloshing”, you know it has a leakage.

– Check the weight of the float: should be 7 gram (except for some R24 – R27 carburetors that use 11 gram floats). An 11 gram float will give a slightly higher fuel level in the float bowl, but the upward pressure on the float needle will be the same: the 7 and 11 gram floats have the same dimensions (=volume), so the “fuel displacement” is the same. The weight of the extra fuel in the float bowl is compensated by the extra weight of the 11 gram float. Examples of carburetors with 11 gram floats: 1/26/46, 1/26/52 (for R26) and 1/26/79, 1/26/83, 1/26/93 (for R27)

– A worn or damaged float needle and/or needle seat in the cover is another cause. Can sometimes be repaired by “grinding” the needle tip in the seat of the cover, using a very fine grinding paste. You have to do this with the needle exactly in a 90 degrees angle. Gluing a long thin round stick to the float needle can make this easier. In the case of the early long model float needle on the twin carbs, a lathe would come in handy.

– Small dirt particles could get stuck between the float needle and the needle seat. If this happens repeatedly, installing a filter in the fuel line and/or cleaning the tank is recommended

– Check the bottom seat of the needle, make sure it’s clean and that the needle can move freely (not applicable to the later model short needles)

– Check that the float needle is not bent. (not applicable to the later model short needles)

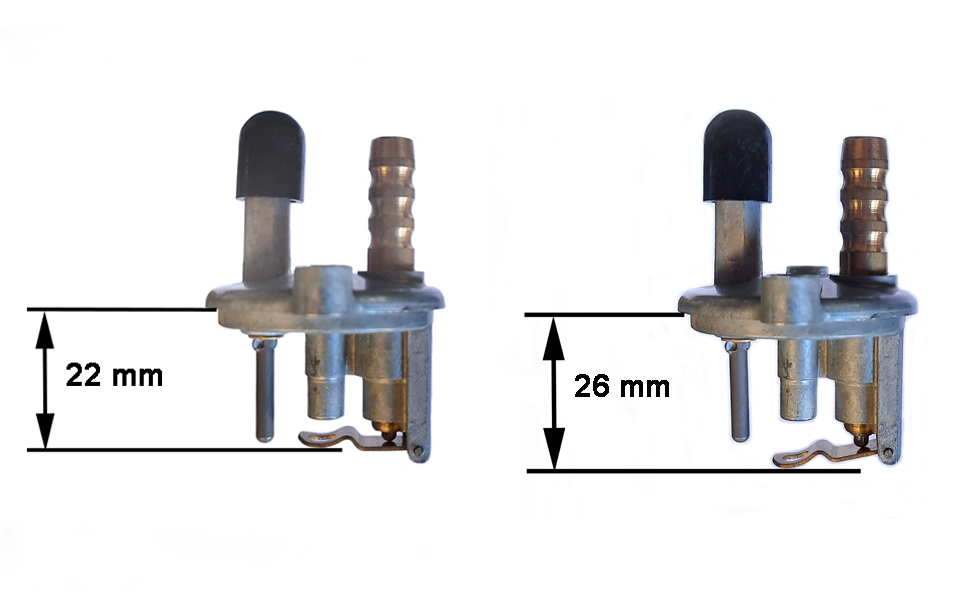

– On later model carburetors (with an off-center fuel hose connection) the lever that operates the float needle may be bent. This may cause the float to rise too high before the needle shuts off the fuel. See photo below how to check the correct setting of the lever. The early models had a “top hat” shim on top of the float. In 1968 BMW changed the float level on the R50/2 – R69S models by replacing the “top hat” shim with a lower flat shim, increasing the fuel level in the float chamber. This is described in detail in the Barrington R50 – R69S manual. Check if the shim is there (P/N13111252179) If the float cover is leaking via the gasket of the float cover, check the surface of the float bowl seat: you may find small cracks / damages that cannot be sealed by the paper gasket.

If the float cover is leaking via the gasket of the float cover, check the surface of the float bowl seat: you may find small cracks / damages that cannot be sealed by the paper gasket.

Check the flatness of the float cover: the “ears” or even the whole cover may be bent. Can straightened, either by carefully pressing it back (only support the “ears”) or flattening it on a lathe.

When the screw caps on the underside of the carburetor keep leaking (after having installed new gasket rings), then the probable cause is the condition of the seat of the carburetor gasket.

If you look closely, you will probably notice that the surface is rough, damaged or scratched.

The solution is NOT to further tighten the screw cap: the gasket ring is not flexible enough to fill these small damages.

The seats of the gasket rings can be machined, but if the damages are not too deep they can be removed by sanding the seat with a very fine grit of (water proof) sand paper. Use a sanding block to make sure that the gasket seat remains flat.

On some carburetors the screw cap of the main jet lies a bit deeper than the adjacent screw cap: when using sanding block, more material will have to be removed from this gasket seat to reach to the surface of the main jet gasket seat.

It is worth noting the following statement from Oldtimer Vergaser Germany in their technical documentation (translated from German):

quote” Today’s gasoline has many disadvantages for our classic bikes. One disadvantage is the consistency, because today it is much more “liquid” than it was back then. This has the consequence that the fuel “pulls”, so its adhesion is much stronger. As a result, the fuel tends to stick to the carburetor walls, etc. pulling itself up and pushing through the unsealed areas, even though they are quite a bit above the float level. This can be observed in particular with all carburetors with a high float level (BMW etc.), because here petrol often escapes from the idle air holes, especially after the engine has been switched off. The same applies to adjusting screws or mixing chamber air openings for primary air or brake air ………..”unquote